Ken Purdham

Bachelor of Arts History & Politics

Diploma of Professional Writing & Editing

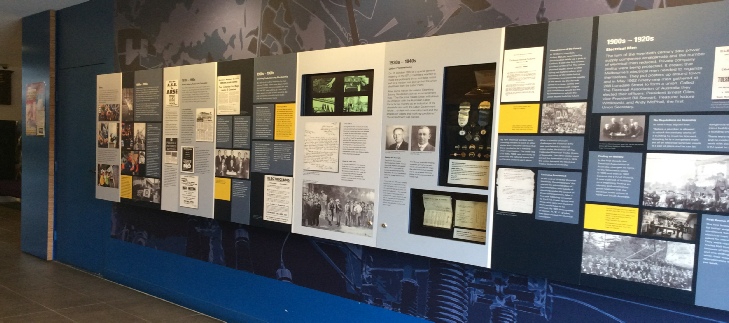

The Electrical Trades Union, Victorian Branch believes its past is as important as its future. To that end its offices include museum displays that track a timeline of trades and union history from 1902 to now.

This Union looks to its future from the platform of its past. It values its place in the community. With that in mind it welcomes educational inquiries about its history within industry, within the political system and within the labour movement.

Contact: ETU on above link or ken. purdham@etuvic.com.au

The union archive collection includes:

- Trade-

union ledgers, journals and magazines - Audio and video interviews with members and officials

- Photographs

- Books & booklets -

technical, political, historical - Trade related documents

- Banners and Posters

- Electrical trade tools and test equipment

- University theses

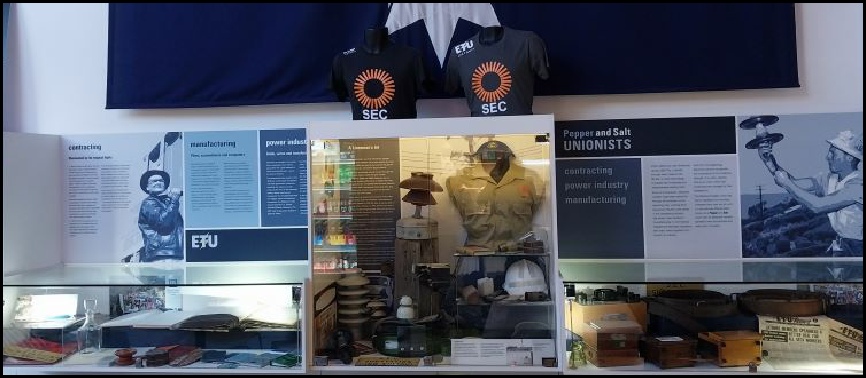

The ETU is sometimes referred to as a pepper and salt union in that its members are sprinkled over all industries. But it all began with the poles and wires.

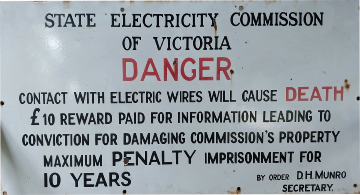

While the newspapers were warning the general public about this new stuff electricity. “If you see a wire off the pole and on the ground don’t touch it. If possible train your dog to to pick it up…” electrical men were busy installing small private power generators and transmission lines to supply Melbourne city blocks.

From those small beginnings electricity and electrical workers began a long association with Australian people and businesses.

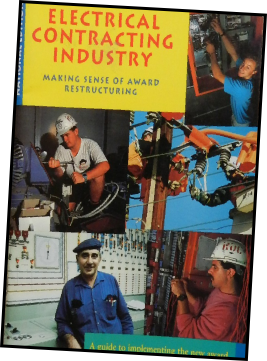

Behind the scenes their union has worked with organisations to secure electrical standards, electrical licensing, training, and safety.

But more than that it has tirelessly supported members’ local communities in many charitable ways.

Click picture to march to top of page

ETU Historian

This month in the virtual museum

Until the late 1960s, machines in modern factories, were controlled by relay logic. Big cabinets with relays and contactors clicking in and out as the machine or process control demanded it. For the machines to work properly, all these relays had to be hardwired in a very specific order, and if one relay had an issue, the whole system would often not work. Troubleshooting could take hours, and because coils fail and contacts wear out, it meant lots of troubleshooting.

Big companies with automated businesses were saying there has to be a better way and on New Year’s day 1968 General Motors put out a set of requirements for something new. They called for a “standard machine controller.” Besides replacing the relay system, the requirements listed by GM included:

A solid-

Easily maintained and programmed in line with the already accepted relay ladder logic way of doing things.

It had to work in an industrial environment with all its dirt, moisture, electromagnetism and vibration.

It had to be modular in form to allow for easy exchange of components and expandability.

The programming look of the PLC required that it be easily understood and used by maintenance electricians and plant engineers.

Bedford Associates headed by Dick Morley was the one accepted. He proposed something called a Modular Digital Controller (MODICON) and with that the MODICON 084 brought the world’s first PLC into commercial production.

The PLC is now arguably the most widely used product in the industrial automation business, with a worldwide market of several billions of dollars per year.

Click picture to go to website

On my union page I tell the story of Freddie Hooks. After an accident, that caused horrific injuries, he fought to rebuild his life and rebuild it he did.

Year 1989

Programmable Logic Controllers (PLCs)

Year 2000

Year 2016

Always

Square D SymMax 400 circa 1991

Seimens LOGO Circa 2010s